It is a long procedure to get a pair of glasses completed, firstly, we load the dried raw plastic particles into the injection pipe, after melt down by high heat, it will then be injected into the mold, after a few seconds cooling, the rough frame and lens is half done. Secondly, several steps are needed, includes trimming, polishing, spray painting, dual-injection and printing. Meanwhile, the lens blank will be trimmed at a proper size accordingly, and then will be applied for various of coating such as anti-fog, anti-scratch, oleophobic, etc., making the lens multi-functional. At last, we assemble the lens and frame together, the eyewear is finally completed.

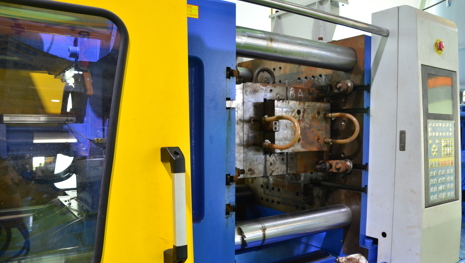

Injection Machine

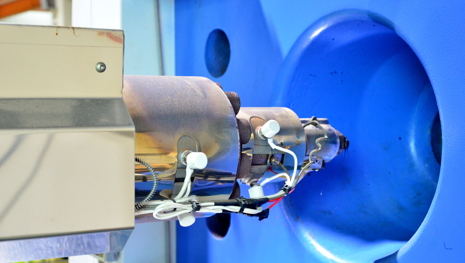

Injection Tube

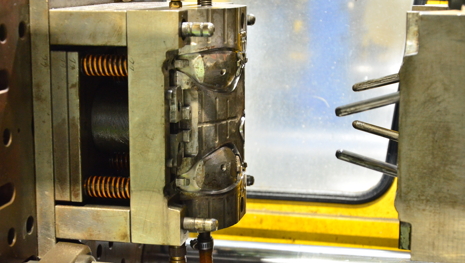

Mold

Vibration Polish Machine

Polishing

LOGO Printing/Stamping

Lens Edging

Assembly & Packing

Truck Loading & Shipping